Nanoparticles in oils are certain materials that help reduce friction between surfaces under load.

Oils with such particles are able to provide better lubrication at higher temperatures compared to traditional oils. The viscosity of these compounds due to their layered structure at the molecular level and the weak connection between the layers themselves. Such layers are able to slide relative to each other with minimal applied force, which is why they lead to high viscosity of the component. However, it is not only the layered structure that improves lubrication. There are some substances with simpler structures that function well as lubricants in certain applications such as Polytetrafluoroethylene (PTFE or Teflon®).

The most famous components are:

- Graphite. (C)

- Molybdenum disulfide. (MoS2)

- Hexagonal Boron Nitride (hBN)

- Polytetrafluoromethylene (PTFE or Teflon®)

| Product | Coefficient of Friction | Working temperature |

| Graphite | 0.11 to 0.2 | 450°C – 538°C |

| Molybdenum | 0.10 to 0.15 | 343°C – 399°C |

| Teflon® | 0.06 to 0.10 | 260°C – 302°C |

| Cerflon® | 0.06 to 0.09 | 260°C – 302°C |

| Ceramics | 0.08 to 0.12 | 2,200°C – 2,760°C |

Solid particles in oil (dispersions)

Solid particles, qualitatively created and dispersed in the oil, lead to unique properties. Although they could be used alone as chemical additives, they are the balance of properties required for many industrial heavy duty engines.

It is also important that professional automotive oils and lubricants can be obtained only with an ideal combination and proportions of oil with an active component.

Features of oils with solid particles:

- They reduce friction and lead to the following factors:

- Reduced energy costs

- Fuel economy

- Reduced operating temperature

- Better fuel combustion

- Smoother engine operation

- General cleaning

- They increase the carrying capacity:

- Faster and easier break-in

- Short procedure for commissioning

- They absorb shock and prevent wear due to vibration:

- Ideal for heavy loads

- Increased life of engine elements

- Reduced cost of maintenance

- Great working time

- They remain effective longer:

- Do not need frequent replacement

- They are able to work in dry conditions:

- They protect the engine even with a lack of oil

- Wide temperature range

Size of nanoparticles in oil

Particle size is important because in a solid/liquid system the settling velocity is proportional to the square of the particle diameter. If the particle size is halved, the sediment action rate is reduced by a factor of four. Therefore, control of particle size is important to maintain the effectiveness of the compound.

Nanoparticles pass through car filters reasonably well without clogging or building up. Particles in olives are smaller than blood cells and invisible to the naked eye.

Stability

In addition to the particle size, the stability of the compound is also important. When dispersions are not stable, they will clump, that is, small particles will collect, pile up, and settle quickly. This can be prevented by coating the particles with a layer of stabilizer that prevents such agglomeration.

A properly designed stabilizer is an important partner in compounds. Colloidal dispersions have a long shelf life, with little or no dissolution. Thus, it is not necessary to always keep the substance at working temperatures for work.

Solid particles in XENUM oils

Ceramics

Xenum developed the concept of ceramic composite technology: particles ceramics or hexagonal boron nitride (hBN), dissolved in oil.

A combination of exceptional lubricating properties of base oils ceramics (hBN) and esters results in a product that has no equal in terms of performance. Polar properties of esters and ceramics not only create a strong oil film, but also keep micro-hBN particles in suspension, allowing for longer quality performance.

Ceramic composite applications, used in such products as VRX 500 and other oils with ceramics, reduce friction and maintain efficiency for a long time.

This results in increased power, lower fuel consumption, less pollution, reduced CO2 emissions and slower wear and tear.

This technology is very suitable as an additive for heavy and sports engines, as well as for industry.

Particles hexagonal boron nitride (hBN), used in Xenum oils, are extremely small (0.25 microns) and do not clog filters, as they do not collect in larger particles - clots.

The most popular products with this technology:

-

Motor oil with ceramics XENUM VRX 5W401 001 UAH

Motor oil with ceramics XENUM VRX 5W401 001 UAH -

Highly effective universal grease with ceramics and Teflon XENUM SUPER 5.1 500 ml (4038500)284 UAH

Highly effective universal grease with ceramics and Teflon XENUM SUPER 5.1 500 ml (4038500)284 UAH -

High-temperature aerosol grease with ceramics XENUM C1200+ 500 ml (4052500)417 UAH

High-temperature aerosol grease with ceramics XENUM C1200+ 500 ml (4052500)417 UAH -

Transmission additive with esters and microceramics for manual transmission XENUM VRX GEAR (3130100)990 UAH

Transmission additive with esters and microceramics for manual transmission XENUM VRX GEAR (3130100)990 UAH -

XENUM CE 300 ceramic oil additive (3123301)810 UAH

XENUM CE 300 ceramic oil additive (3123301)810 UAH -

Oil additive with esters and microceramics XENUM VRX 5001 646 грн – 3 832 грн

Oil additive with esters and microceramics XENUM VRX 5001 646 грн – 3 832 грн -

Motor oil with ceramics XENUM VRX 7.5W401 001 UAH

Motor oil with ceramics XENUM VRX 7.5W401 001 UAH -

Motor oil with ceramics XENUM VRX 5W301 014 UAH

Motor oil with ceramics XENUM VRX 5W301 014 UAH

Cerflon®

Cerflon® is the temptation that occurs when to fluoropolymer (PTFE) add strength boron nitride, thereby "strengthening" the properties.

This compound significantly increases strength and wear resistance. Cerflon® is a patented technology of the Xenum company.

It is used in the following products:

-

Universal aerosol lubricant with Cerflon® XENUM XC LUBE 500 ml (4014500)488 UAH

Universal aerosol lubricant with Cerflon® XENUM XC LUBE 500 ml (4014500)488 UAH -

Liquid key, lubricant XENUM DEBLOCK SHOCK (4076500)443 UAH

Liquid key, lubricant XENUM DEBLOCK SHOCK (4076500)443 UAH -

Highly effective synthetic lubricant for chains with Cerflon® XENUM CHAIN PRO 500 ml (4090500)488 UAH

Highly effective synthetic lubricant for chains with Cerflon® XENUM CHAIN PRO 500 ml (4090500)488 UAH -

Highly effective universal grease with ceramics and Teflon XENUM SUPER 5.1 500 ml (4038500)284 UAH

Highly effective universal grease with ceramics and Teflon XENUM SUPER 5.1 500 ml (4038500)284 UAH

Carbon-Graphite

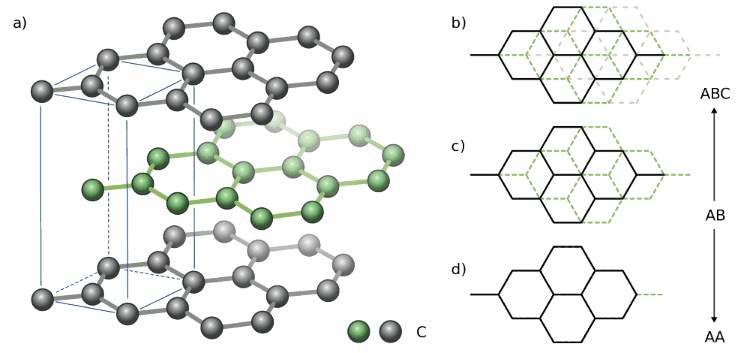

Carbon-Graphite technology is dispersion graphite nanoparticles (C) in oil.

These particles are very small (1μ) and consist of an infinite number of hexagonal carbon crystals with a crystalline structure. Xenum motor oils based on graphite offer an economical alternative to top-class oils based on esters and ceramics.

It is used in the following products:

-

Lubricant additive for grease with esters, graphite and molybdenum XENUM SUPER G582 грн – 1 171 грн

Lubricant additive for grease with esters, graphite and molybdenum XENUM SUPER G582 грн – 1 171 грн -

Lubricant additive with esters and graphite for worn engines XENUM XG 100K (3239350)989 UAH

Lubricant additive with esters and graphite for worn engines XENUM XG 100K (3239350)989 UAH -

Motor oil with graphite XENUM GPR 10W60720 UAH

Motor oil with graphite XENUM GPR 10W60720 UAH -

Motor oil with graphite XENUM GP 10W40550 грн – 10 000 грн

Motor oil with graphite XENUM GP 10W40550 грн – 10 000 грн -

Motor oil with graphite XENUM GPX 5W40667 UAH

Motor oil with graphite XENUM GPX 5W40667 UAH

If you need consultation or advice about your car, contact the specialists of Xenum Ukraine.