In our last article we compared MoS2 (Molybdenum) , Teflon and Graphite in terms of lubricating properties.

It's time to talk about the undisputed leader of this issue: ceramics (or boron nitride). It is also called "white graphite".

Ceramic powder with hexagonal boron nitride molecules is the best additive component. Let's find out why he is.

Productivity

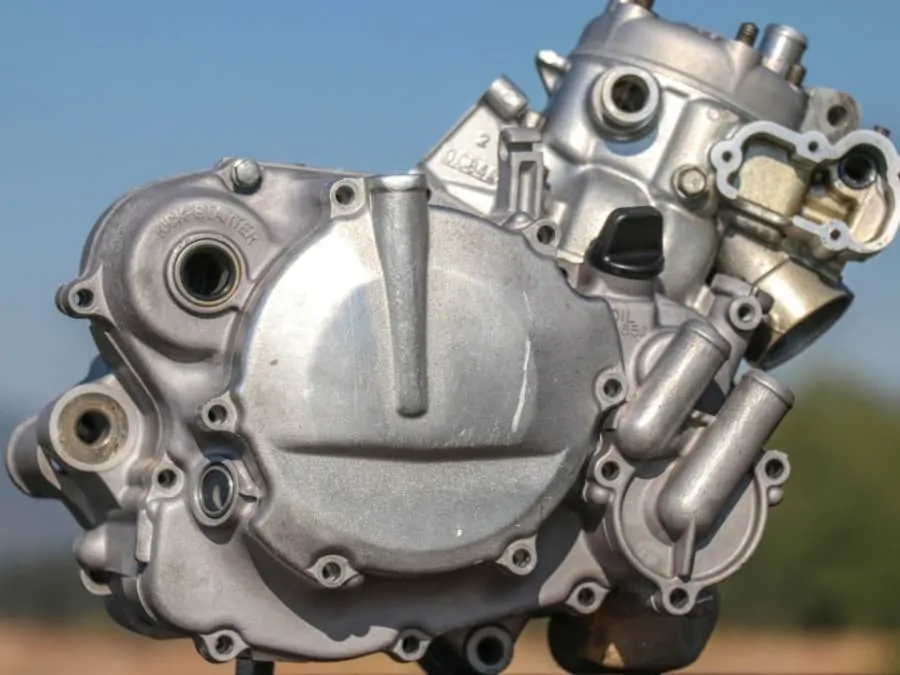

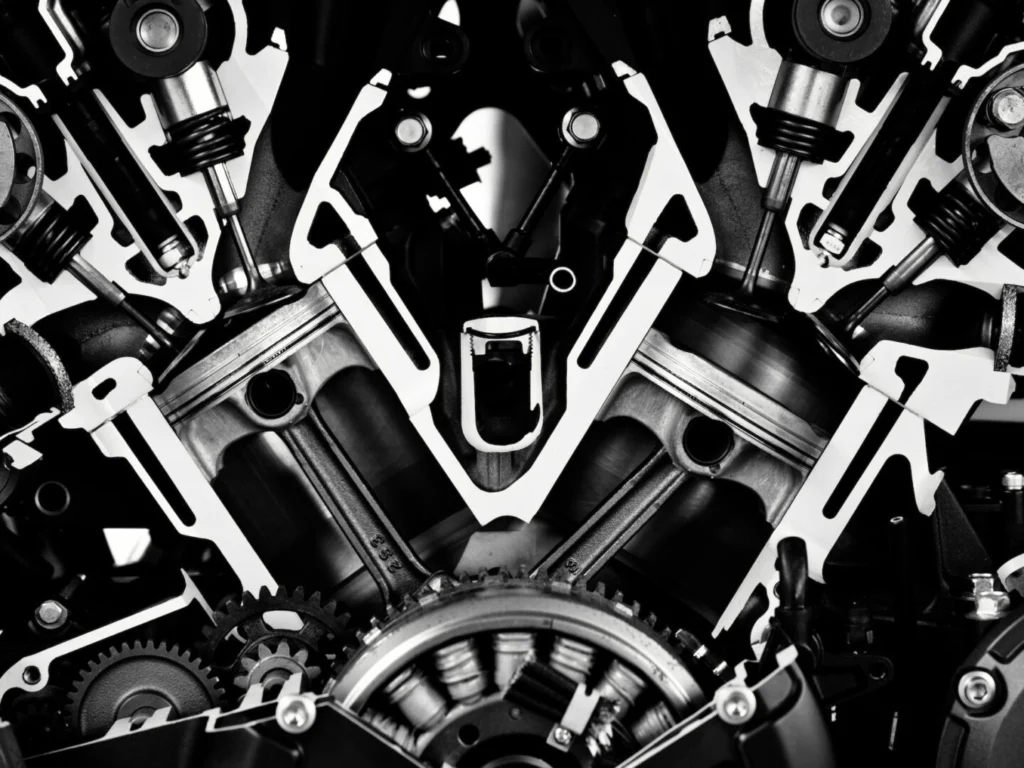

When we talk about particles in oils, we mean materials capable of reducing friction between two surfaces. The main advantage of such additives is that they significantly slow down the wear process of engine elements while improving the properties of the oil.

After analyzing the other 3 applications (PTFE - Teflon, MoS2 – Molybdenum and Graphite), we have already talked about their differences and uses, as well as the advantages of each of them.

That is why we would now like to start by showing you the numbers and the research.

As we go down the table, we see how each material generally performs better than the previous one.

And when we come to boron nitride, we notice that this lubricant superior in all aspects. Ceramics easily withstand wear (D-4172) and extreme pressure (D-3233). Moreover, it, like PTFE and MoS2, performs well in extreme temperatures (D-2670) and kinetic friction tests (Falex).

You can also see that the winner is Cerflon® mentioned in the article about PTFE (Teflon), has a general advantage.

However, as always, we must consider all the points. As we mentioned earlier, the problem with Cerflon® and PTFE is their operating temperature range. Cerflon® ceases to be effective at temperatures close to 300 ºC, while ceramics can withstand more than 1000 ºC.

Accessories with ceramics from Xenum

As with graphite, the potential of this application only prompted further research. That's how it appeared the VRX product line.

If you are planning to change the oil in your car, we recommend that you try a VRX representative. We currently offer 5W30, 5W40 and the exclusive 7.5W40.

On the other hand, if you have recently changed your oil, we recommend our best additive VRX 500. This additive contains the highest concentration of ceramic particles (hBN ) and is available in larger quantities than its best replacement, CE 300.

It's also worth mentioning that our VRX range is officially 41% low friction tested by a prestigious organization TÜV (test report No PB 8141.198.08).

Stay connected!

Leave your contacts to receive our newsletter with a discussion of our products and modern technologies.

automatic transmission (automatic)

automatic transmission (automatic) MKP (Mechanics)

MKP (Mechanics) Lubricating system

Lubricating system Fuel system

Fuel system Cooling system

Cooling system